John Hart's mill at Port Adelaide from 1855 sets British-empire quality standards for flour and advanced technology

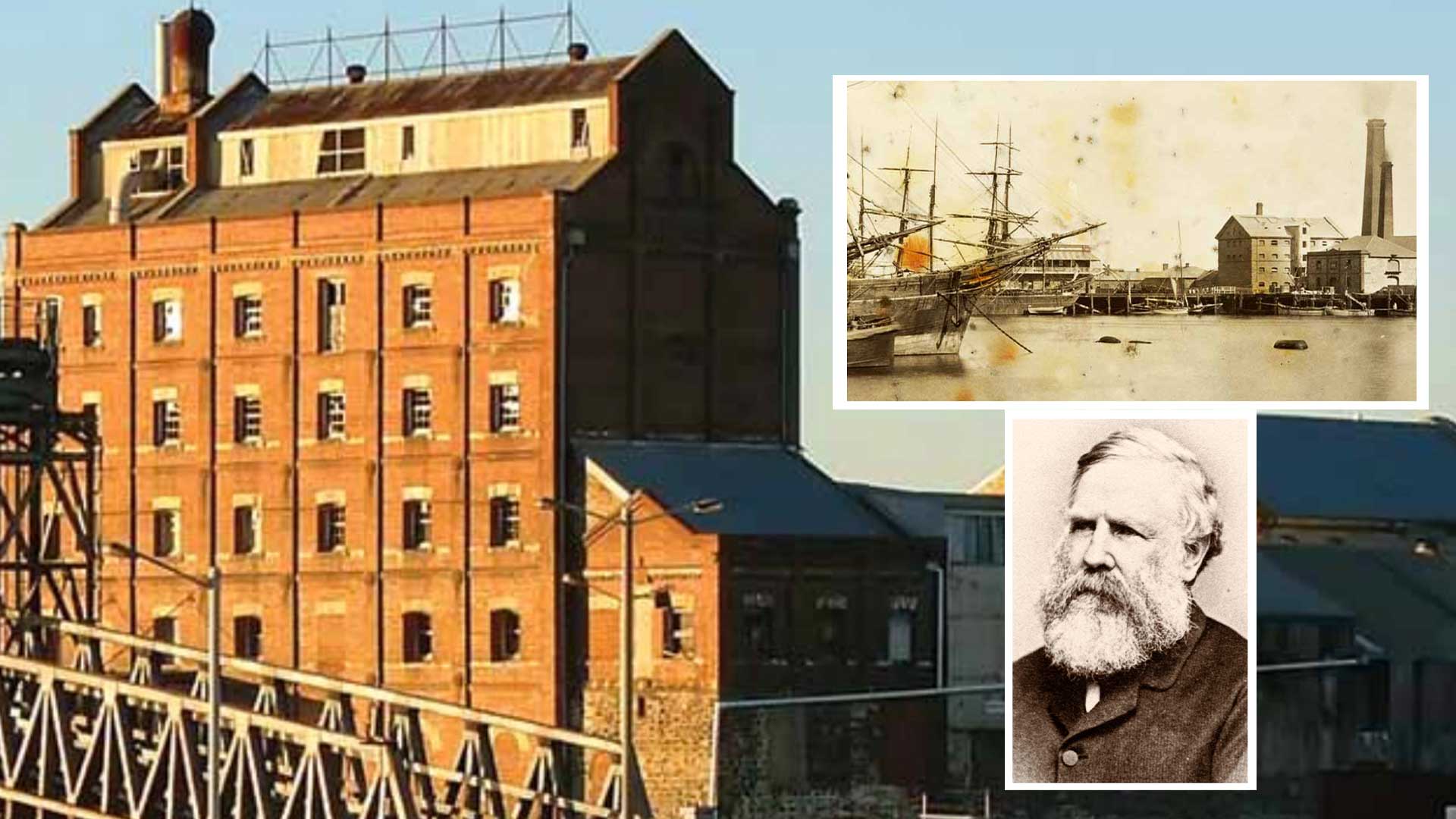

The surviving South Australian state-heritage-listed building (at left) from Adelaide Milling Company at Port Adelaide. Inset, top right: The mill site on the waterfront in the 1880s when it was the largest and most technologically advanced mill in South Australia and claimed to be the best in the southern hemisphere. The towering brick chimney, designed by colonial architect Edward Hamilton, was part of the smelter processing Burra Burra copper. Inset bottom right: John Hart.

Images courtesy State Library of South Australia

Hart’s Mill at Port Adelaide, completed in 1855 for former sea captain and three times future South Australian premier John Hart, was the largest and most advanced mill, handling exports of the young colony’s grain.

In 1843, Hart, with Jacob Hagen, bought land in Port Adelaide from explorer John Hill before sailing to England in command of the South Australian Company's ageing barque Sarah and Elizabeth, to be sold in London.

Back in Port Adelaide, Hart entered the mill venture with pastoralist Henry Kent Hughes, and investors such as James Brunskill, in 1854. Their mill was a five-storey stone building with twin two-cylinder steam engines built by London firm Easton & Amos.

Each mill engine generated 30 horsepower and was linked via geared wheel and pinions to a pair of countershafts. These shafts powered 10 pairs of millstones producing more flour while generating less friction than standard millstones then used. The mill used silk mesh to sift the flour to a fine texture. The mill’s increased capacity allowed employees to examine and ensure the quality of flour with greater frequency.

Hart’s Flour soon had a reputation for quality in South Australia and throughout the British empire. It commanded Australia’s highest flour prices for several years and transformed colonial South Australia’s milling that, within 50 years, greatly enhanced Australia’s status as the world’s eighth largest wheat producer.

Beyond Hart’s death in 1873, his mill had continued for another nine years before being sold when it merged with Duffield’s mills of Gawler, James Cowan Company and Morgan, Cannon and Glynde Company wheat merchants. The new conglomerate company was called Adelaide Milling and Mercantile Ltd but after bankruptcy became Adelaide Milling Company Ltd in 1890 although they marketed wheat under the former brand names of Harts, Duffields, Snowtown and Hawker flours.

To keep up with the demand for South Australian flour, it built a second larger six-storey red-brick mill, completed in 1888. The complex survived fires in 1905 and 1939 to keep operating at some level until 1980, making it the longest continuously operating flour milling enterprise in South Australia.